供应商质量管理主管

1.5-2.5万·15薪杭州市本科不限经验

职位描述

工作职责:

1. 根据公司流程,参与供应商开发过程,对新供应商进行资质审查及审核,对供应商质量管理水平做最终确认,推进并解决新供应商开发过程中的质量相关问题;

Participate in supplier development process according to company process, conduct qualification and audit of new suppliers, make final confirmation of supplier quality management level, promote and solve quality related issues in new supplier development process.

2. 针对不同类型物料供应商,确定供应商开发过程中的重要节点和关键风险,确定风险接收准则并要求供应商遵照落实;

For different material suppliers, identify important nodes and key risks in the development process of suppliers, determine risk acceptance criteria, ask suppliers to implement accordingly.

3. 领导开展监督供应商质量体系管理工作。针对不同的物料供应商,设计合适的供应商审核标准;

Lead to monitor supplier quality management system, develop appropriate supplier audit criteria for different material suppliers.

4. 根据公司相关流程,领导制定供应商审核计划并实施供应商审核,出具详细的审核报告;制定整改计划,跟踪整改计划的落实,确保不合格项的有效关闭;

Lead to set supplier audit plan and implement supplier audit according to company's related process, issue detailed audit report, set improvement plan, formulate a rectification plan, track the implementation of the rectification plan to ensure the effective closure of non-conformities.

5. 了解供应商的生产流程和关键控制点, 帮助供应商在生产过程和质量控制等方面持续改善;

Understand supplier production process and critical control points, help supplier continually improve in production process and quality control.

6. 针对标准机型关键物料的开发,参与样品确认(PPAP);

Participate in the development of key materials for standard models and be involved in sample evaluation (PPAP).

7. 定期召开主要供应商质量例会,同步质量目标、通报问题进展,明确后续改进要求。

Regularly hold quality meetings with major suppliers, synchronize quality targets, report progress on issues, and clarify requirements for subsequent improvements.

8. 与供应商一起迅速解决发现的质量问题,分析根本原因,制定最终纠正预防措施和改进计划,负责督促相关计划的落实、措施的跟进及验证;

Work together with suppliers to solve quality issues quickly, analyze root cause , set final corrective and preventive actions plan, follow up and verify improvement actions.

9. 制定及完善供应商质量管理方面的程序、各项相关的质量审核文件、相关质量绩效考评文件、检验标准、检验记录等文件,根据工作需要实施现场检验;

Prepare and optimize procedures, audit standards, quality performance evaluation documents and records in supplier quality management. Implement on-site inspection when required.

10. 定期汇总供应商质量绩效、供应商质量管理和改进行动计划、重大供应商质量问题(PIR)的处理进展及其他必要的信息、数据,归档沟通记录,定期向上级领导汇报;

Regularly summarize on supplier quality performance, action plans for supplier quality management and improvement, progress in handling major PIR related to supplier quality issues and other necessary information & data, filing communication records, and report to leaders regularly.

11. 完成其他交办的工作。

Other duties as assigned.

任职资格:

1. 制冷、电气自动化、机械设计本科或以上学历;

Bachelor degree or above in refrigeration, electrical automation or mechanical design.

2. 书面英语良好;

Good Written English.

3. 8年以上质量管理经验;

Above 8 years working experience in quality management.

4.熟悉ISO9001质量管理体系;

Familiar with ISO 9001Quality Management System.

5. 熟悉质量管理方法及工具8D问题解决方法;

Quality management methods and tools, 8D problem solving.

6. 熟悉供应商开发流程,熟悉风险分析工具,如FMEA,掌握各类供应商审核技巧;

Familiar with supplier development process & risk analysis tools, such as FMEA, all kinds of supplier audit skills.

7. 熟悉办公软件,对生产工艺和产品技术有一定的了解,能看懂图纸;

Familiar with MS Office Software, a certain degree understanding of production process and product technology, able to read drawings.

8. 熟悉空调关键零部件控制要求,如压缩机、冷凝器、节流装置和蒸发器;

Be familiar with control requirements of key air-conditioning components, such as compressor condenser throttling device and evaporator.

9. 良好的沟通协调能力.

Good communication and coordination skills.

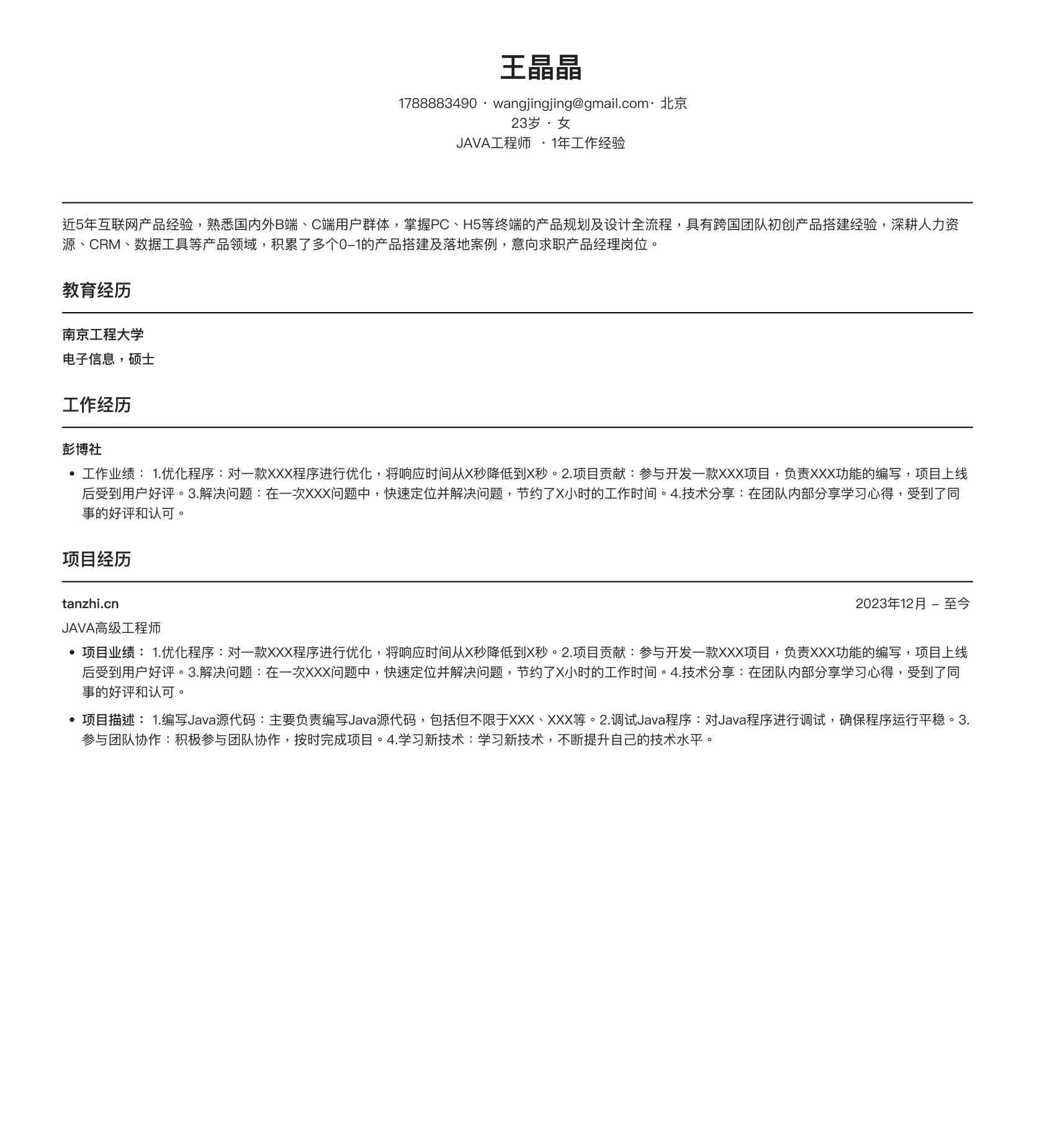

简历是否与目标岗位匹配?

为什么没有面试?我的简历有什么问题?

怎么优化?职业优势在哪里?

投递之前...

你的简历真的准备好了吗

80% 简历因职业定位模糊,表达无焦点

被快速跳过,立即诊断,提升面试机会!